Search This Supplers Products:fabric inspection machinefabric rolling machinefabric folding machinefabric cutting machinewarp beam trolleybeam stacker

- Home

- About us

- Products

- Faqs

- Fabric Inspection Machine

- Fabric Folding Machine

- Fabric Cutting Machine

- Beam Stacker

- Digital Counter Meter

- Fabric Relaxing Machine

- Tubular Fabric Reversing Machine

- Tubular Fabric Slitting Machine

- Automatic Tube-Sewing Machine

- Hydraulic Warp Beam Trolley

- Motorized Warp Beam Trolley

- Cloth Roll Trolley

- Warp Beam

- SUNTECH Service

- Fabric Rolling Machine

- Fabric Roll Packing Machine

- Accessories

- Batcher Machine

- News

- Certificate

- Contact us

SUNTECH Automatic pp spunlace nonwoven fabric machine

- group name

- Nonwoven Fabric Machine

- Min Order

- 1 piece

- brand name

- Suntech

- model

- ST- SLNM

- Nearest port for product export

- Ningbo, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, Express Delivery

- Acceptable payment methods

- T/T, L/C

- Export mode

- Export through agents

- update time

- Thu, 07 Jan 2021 16:05:57 GMT

Paramtents

Name Nonwoven Spunlace Production Line

Model ST- SLNM

Line speed up to 400 m/min (Direct Line)

Capacity 25,000 t/a (Direct Line)

Energy savings up to 35%

Recycled water up to 99%

Width up to 6.6 m

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

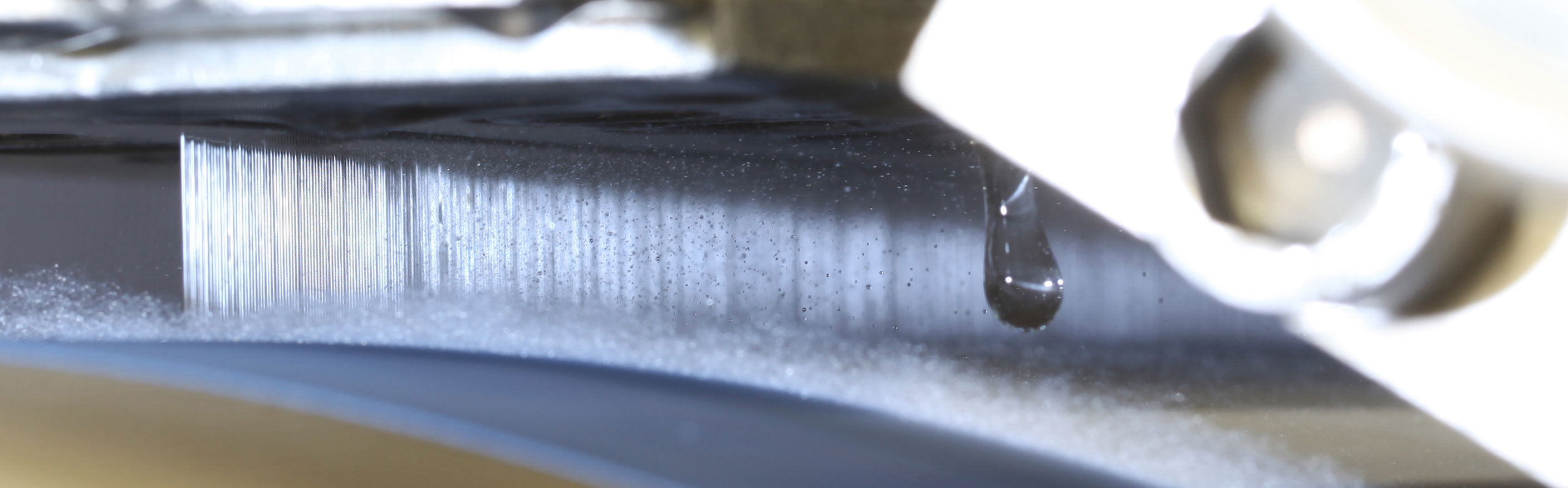

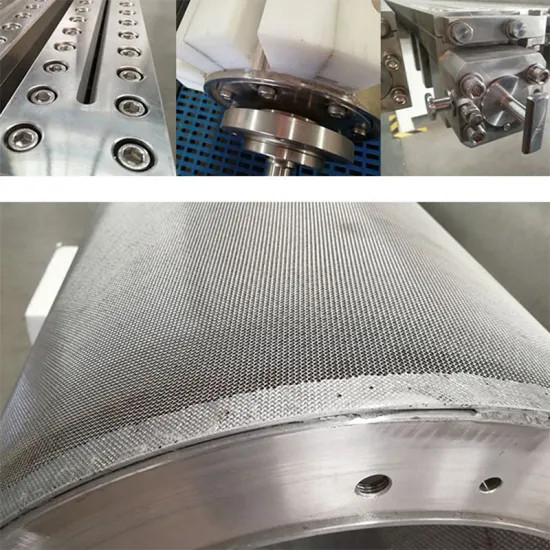

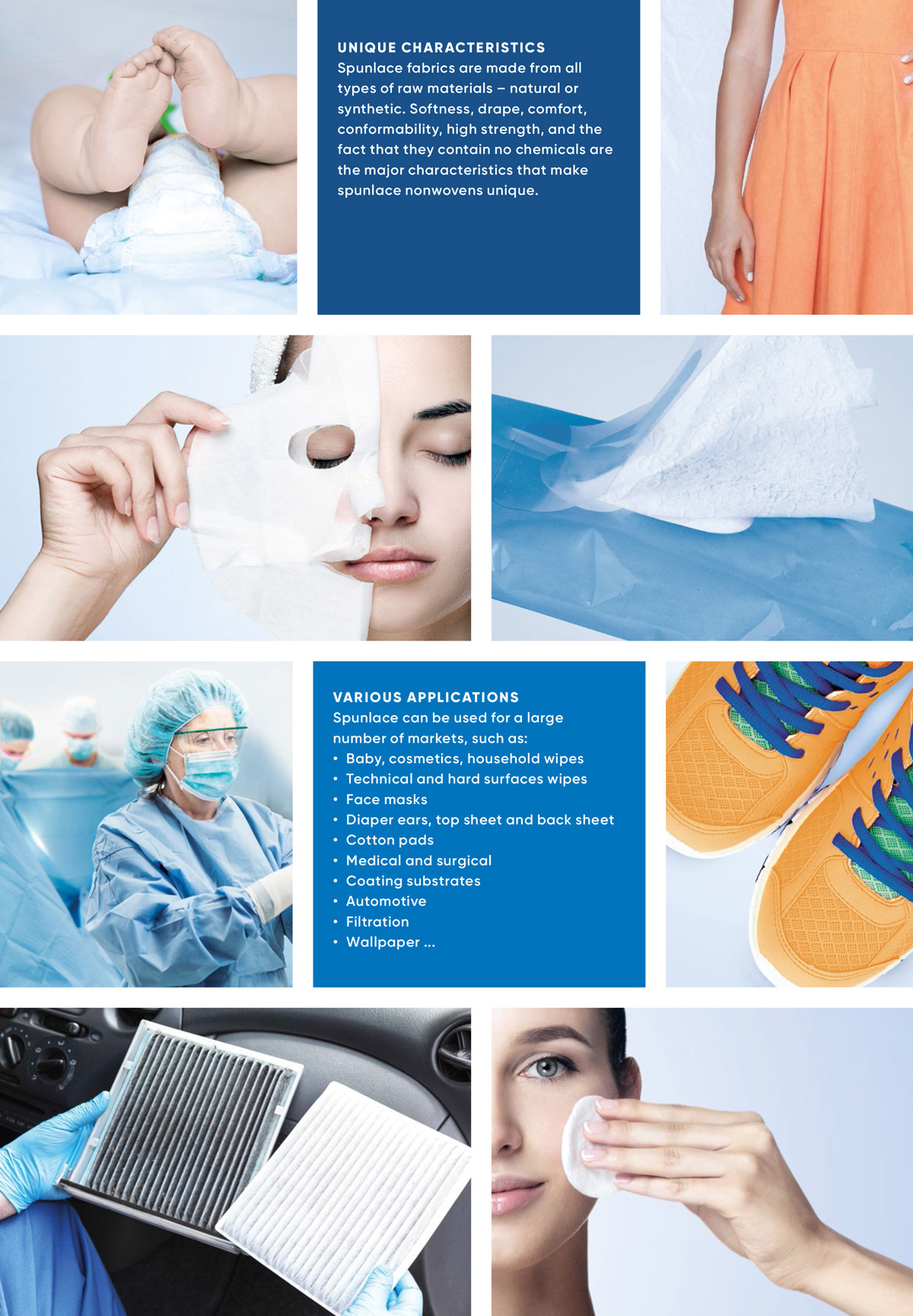

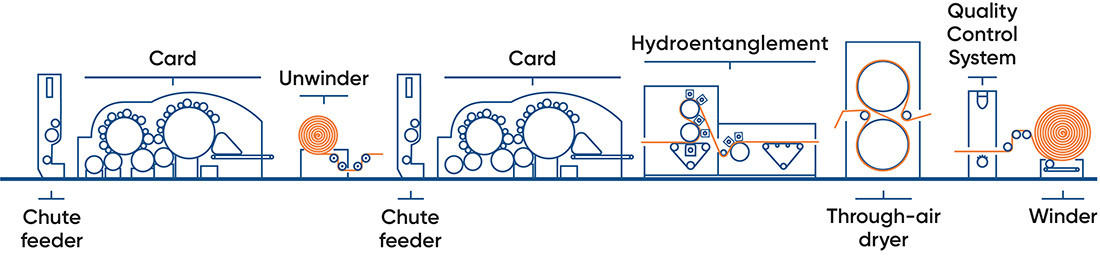

The direct line configurations are mainly designed for lightweight spunlace fabrics using

sub-denier fibers, and for cellulosic fibers.

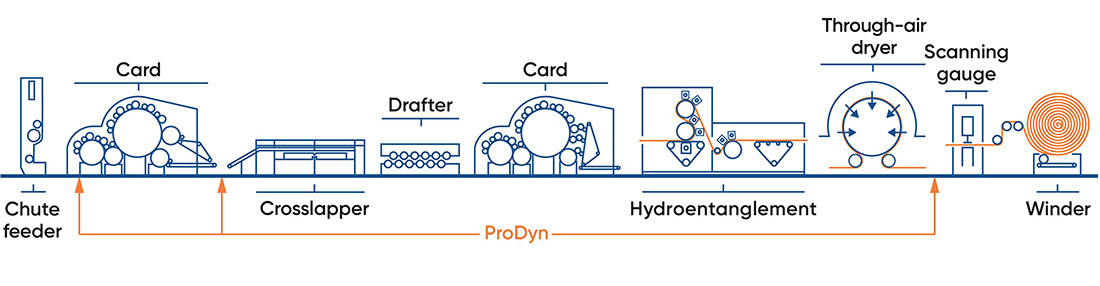

For durable end-uses, crosslapping line configurations are preferred using a wide range of technical fibers such as: PTFE, PA6, PA66, PE, glass fibers, PPS, Kevlar, and so on.

|

Name |

Nonwoven Spunlace Production Line |

|

Model |

ST- SLNM |

|

Line types |

Direct, Crosslapping |

Material | Viscose / Polyester |

Working width | Up to 6.6m |

Fabric Weight(GSM) | 18-120 gsm (Direct Line) |

Line speed | Up to 400 m/min (Direct Line) |

Capacity | 25,000 t/a (Direct Line) |

Energy savings | up to 35% |

Recycled water | up to 99% |

Weight Control | PLC |

Total Power | 4.5-8.5kw |

End uses | Wipes, medical, hygiene (Direct Line) Face masks, automotive, artificial leather, filtration, etc. (Crosslapping Line) |