Search This Supplers Products:fabric inspection machinefabric rolling machinefabric folding machinefabric cutting machinewarp beam trolleybeam stacker

- Home

- About us

- Products

- Faqs

- Fabric Inspection Machine

- Fabric Folding Machine

- Fabric Cutting Machine

- Beam Stacker

- Digital Counter Meter

- Fabric Relaxing Machine

- Tubular Fabric Reversing Machine

- Tubular Fabric Slitting Machine

- Automatic Tube-Sewing Machine

- Hydraulic Warp Beam Trolley

- Motorized Warp Beam Trolley

- Cloth Roll Trolley

- Warp Beam

- SUNTECH Service

- Fabric Rolling Machine

- Fabric Roll Packing Machine

- Accessories

- Batcher Machine

- News

- Certificate

- Contact us

SUNTECH New Arrivel Electric Warp Beam Lift Trolley With Harness Mounting Device

- group name

- Motorized Warp Beam Carriers

- Min Order

- 1 piece

- brand name

- Suntech

- model

- ST-MBT-02I

- Nearest port for product export

- Ningbo, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, Express Delivery

- Acceptable payment methods

- T/T, L/C

- Export mode

- Export through agents

- update time

- Thu, 21 Jan 2021 10:13:52 GMT

Paramtents

Usage weaving beam and heald frame transport

Structure Roll Container

Material Carbon Steel

Wheel Four-wheel

Item Motorized Warp Beam Lift Trolley

After-sales Service Provided Engineers available to service machinery overseas

Carrying Capacity 1000-2500kg

Beam Flange Diameter 800-1250mm

Beam Barrel Diameter 100-400mm

Packging & Delivery

-

Min Order1 piece

Briefing

ST-MBT-02I is suitable for bottom beam transporting, inserting in weaving machines.

Detailed

SUNTECH Motorized Warp Beam Lift Trolley

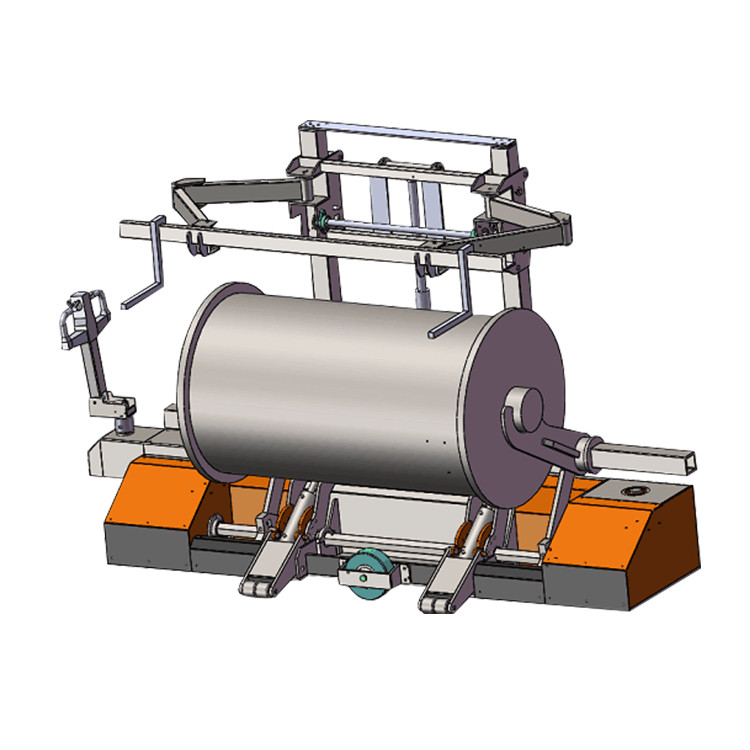

ST-MBT-02I Electric Warp Beam Lift Trolley with Harness Mounting Device is the NEWES MODEL,suitable for bottom beam transporting, inserting in weaving machines. warp beam weighing up to 2000kg and beam width as per requirement. additional loading capacity of 400kg for harness. The trolley is applicable for any weaving machines with their normal working width 170-340cm without changing its size. A transverse of 10cm for easy beam positioning.

The harness is accommodated by the standard take-up for harness frame and the contact rails and dividing rails or the complete warp stop motion.