Search This Supplers Products:fabric inspection machinefabric rolling machinefabric folding machinefabric cutting machinewarp beam trolleybeam stacker

- Home

- About us

- Products

- Faqs

- Fabric Inspection Machine

- Fabric Folding Machine

- Fabric Cutting Machine

- Beam Stacker

- Digital Counter Meter

- Fabric Relaxing Machine

- Tubular Fabric Reversing Machine

- Tubular Fabric Slitting Machine

- Automatic Tube-Sewing Machine

- Hydraulic Warp Beam Trolley

- Motorized Warp Beam Trolley

- Cloth Roll Trolley

- Warp Beam

- SUNTECH Service

- Fabric Rolling Machine

- Fabric Roll Packing Machine

- Accessories

- Batcher Machine

- News

- Certificate

- Contact us

SUNTECH Textile Rolling Winder Machine For Fabric Rolling

- group name

- Fabric Rolling Machines

- Min Order

- 1 piece

- brand name

- Suntech

- model

- ST-RM

- Nearest port for product export

- Ningbo, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, Express Delivery

- Acceptable payment methods

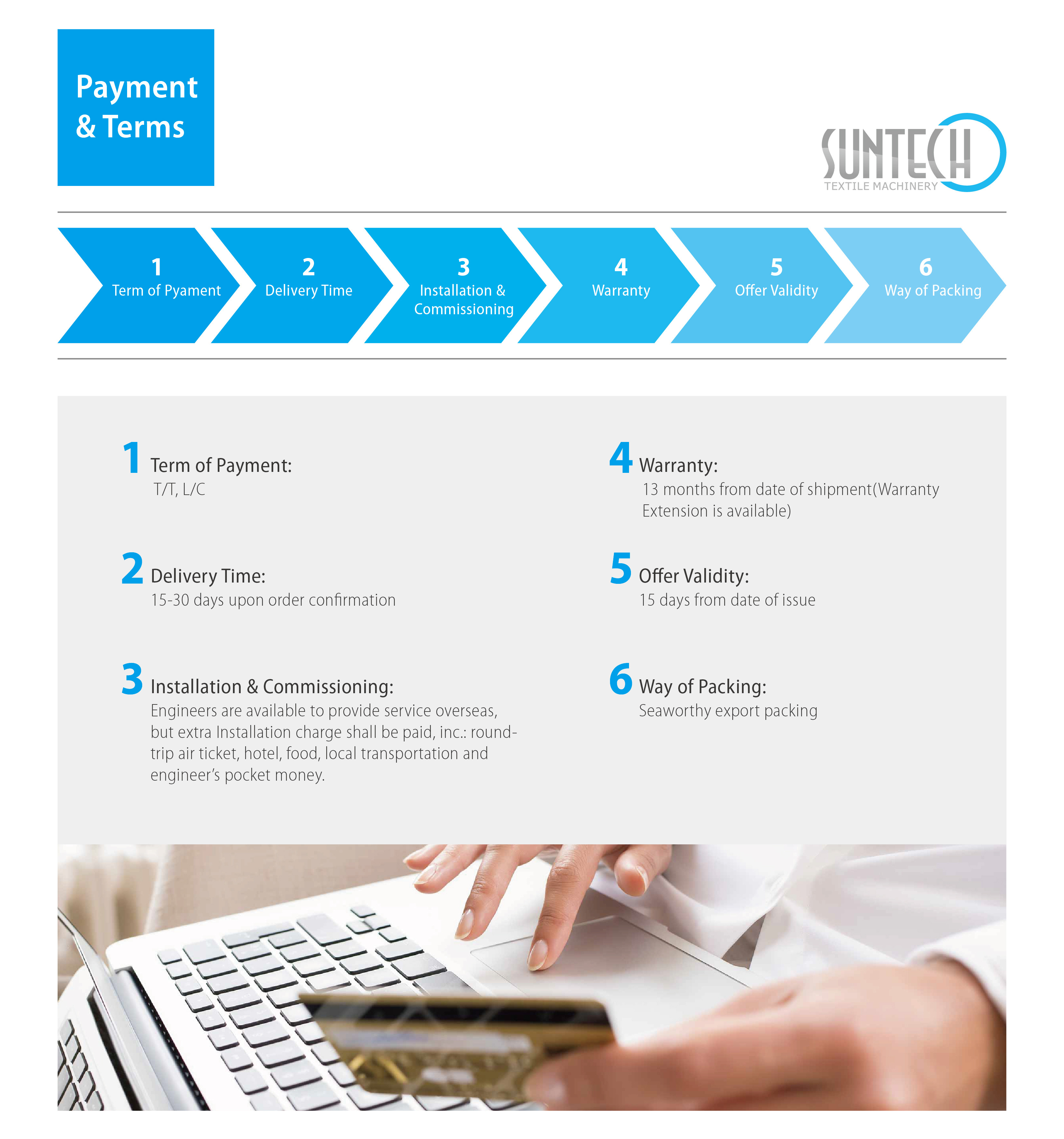

- T/T, L/C

- Export mode

- Export through agents

- update time

- Wed, 17 Apr 2019 10:31:35 GMT

Paramtents

Condition New

Automatic Grade Automatic

Voltage 380V, 50HZ, 3Phase

Power(W) Around 2-3 KW

Dimension(L*W*H) As per Exact Model

Weight As per Exact Model,1000kgs(for model ST-RM-180 only

Certification CE MARK, ISO9001:2008

Warranty 13months or 18 months, 13 Months from date of shipment

After-sales Service Provided Engineers available to service machinery overseas, Engineers available to service machinery overseas

Item FABRIC ROLLING MACHINE

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed