Search This Supplers Products:fabric inspection machinefabric rolling machinefabric folding machinefabric cutting machinewarp beam trolleybeam stacker

- Home

- About us

- Products

- Faqs

- Fabric Inspection Machine

- Fabric Folding Machine

- Fabric Cutting Machine

- Beam Stacker

- Digital Counter Meter

- Fabric Relaxing Machine

- Tubular Fabric Reversing Machine

- Tubular Fabric Slitting Machine

- Automatic Tube-Sewing Machine

- Hydraulic Warp Beam Trolley

- Motorized Warp Beam Trolley

- Cloth Roll Trolley

- Warp Beam

- SUNTECH Service

- Fabric Rolling Machine

- Fabric Roll Packing Machine

- Accessories

- Batcher Machine

- News

- Certificate

- Contact us

Suntech non-woven machine helps the stable development of the non-woven industry chain

time2021/04/15

- The future of non-woven fabric market is promising, suntech non-woven fabric machine helps non-woven fabric production.

The global outbreak of new crown pneumonia in 2020, masks have become a necessity for epidemic prevention and control. The supply of non-woven fabrics, the key material of masks, is in short supply. The price of non-woven fabrics has doubled by 10 times. Industries such as diapers, wet wipes and protective clothing that compete with masks for non-woven fabrics are facing "Life and death", especially in the diaper industry that urgently needed non-woven fabrics, was temporarily discontinued. The non-woven fabric industry chain is broken due to the lack of non-woven fabrics. An epidemic has started the battle for non-woven fabrics. Why is non-woven fabrics so important? Which upstream and downstream industries does it relate to?

Non-woven fabrics are also called non-woven fabrics, which are sheets, webs or pads that do not need to be woven but are oriented or randomly arranged and bonded. It is widely used. Common face masks, diapers, tablecloths, disposable slippers, clothing linings, cigarette filters, etc., all have non-woven components in daily life. It can be said that people’s daily life cannot do without non-woven fabrics.(Click to share to LinkedIn)

Dismantling of the non-woven fabric industry chain:

1.Upstream material: viscose fiber, polyester fiber, polypropylene fiber

2.Midstream processing: non-woven fabric manufacturing

3.Downstream applications: agriculture, industry, automobiles, leisure, tourism, clothing, office, construction, etc.(Click to share to Facebook)

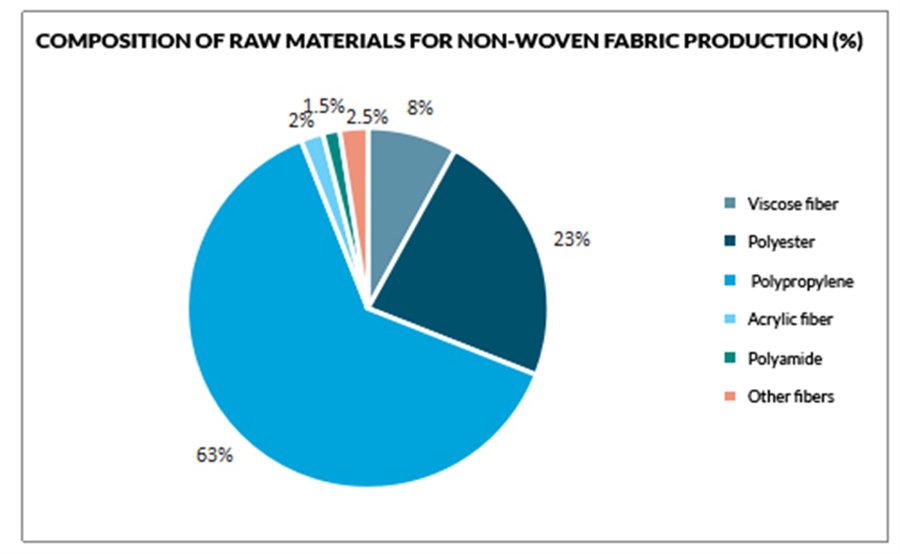

Analysis of upstream raw materials of non-woven fabrics

The three major fibers used in the production of non-woven fabrics are polypropylene (63% of the total), polyester (23% of the total) and viscose fiber (8% of the total), and the remaining 2% are acrylic fiber, 1.5 % Is polyamide, 2.5% is other fibers.

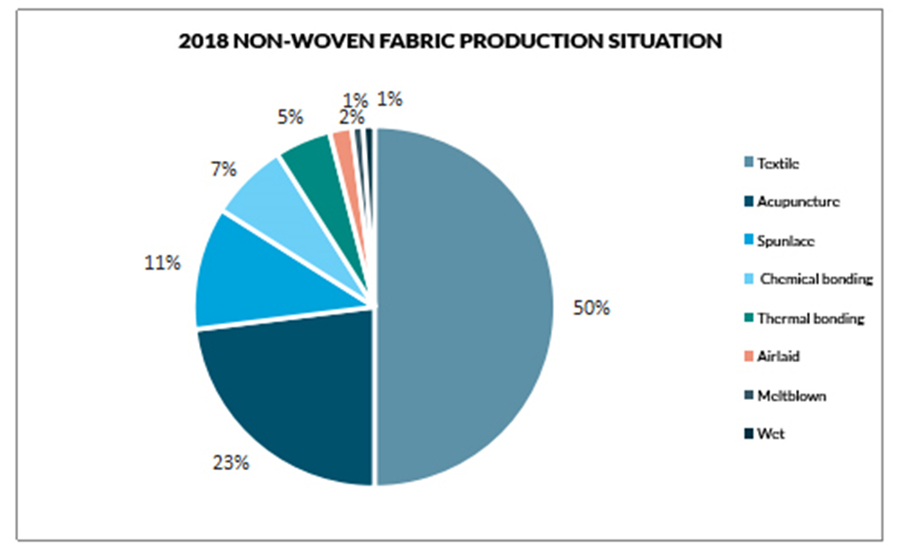

Non-woven fabrics can be divided into spunbonded, spunlaced, needle punched, chemical bonding, thermal bonding, meltblown and other types. Spunbond, spunlace, and needle punching are the three mainstream production processes in the industry, accounting for more than 80%. Spunbond is the most widely used non-woven fabric production process in the world. Spunlace non-woven fabrics have grown rapidly in recent years, mainly due to the pull of downstream medical and health, nursing and beauty needs.(try Suntech ST-AMB Meltblown machine)

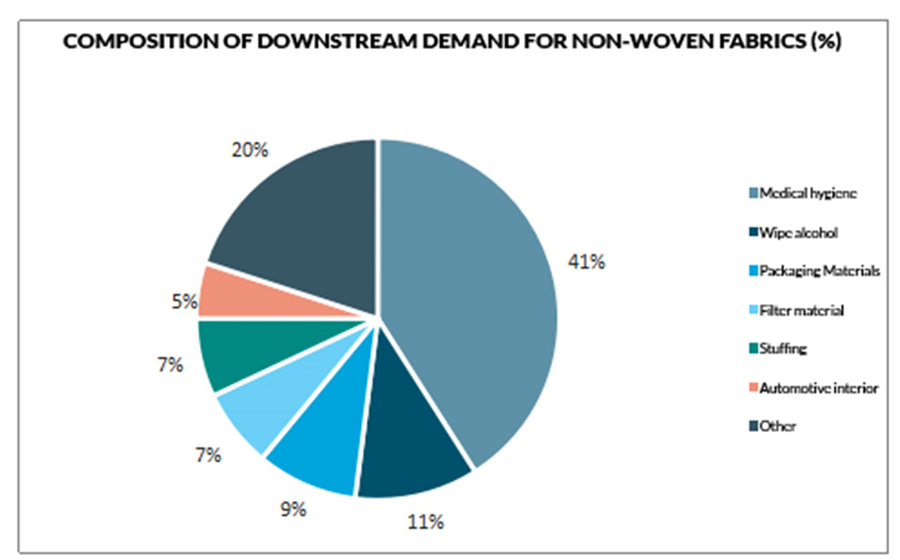

Non-woven downstream analysis

Different production processes have different characteristics, and their downstream applications also have significant differences. Divided by product use structure, medical and sanitation is the number one use of non-woven fabrics, accounting for 41%. In recent years, with the increasing awareness of downstream consumption upgrading, the penetration rate of cotton soft towels, facial wipes, facial masks and other categories has increased, which is an important force in the development of non-woven fabrics.

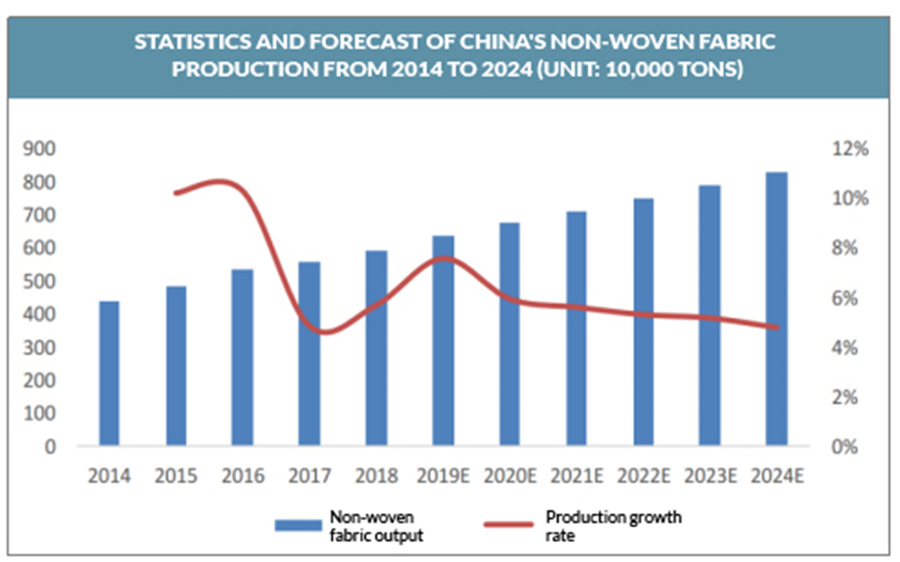

Analysis of China's non-woven fabric market

China is the world's largest non-woven fabric production and consumption country. In 2018, the annual output of various non-woven fabrics in my country reached 5.932 million tons, an increase of 196.31% over 2008, with an average annual compound growth rate of 11.47%. my country's non-woven fabric production can still maintain a high single-digit growth rate in the next five years. Driven by the new crown pneumonia epidemic, the growth of non-woven fabrics will inevitably exceed previous estimates. In addition to the medical demand brought about by this epidemic, the areas where the demand for non-woven fabrics is growing faster include sanitary napkins, baby diapers, adult incontinence products and Other cleaning and wiping products.

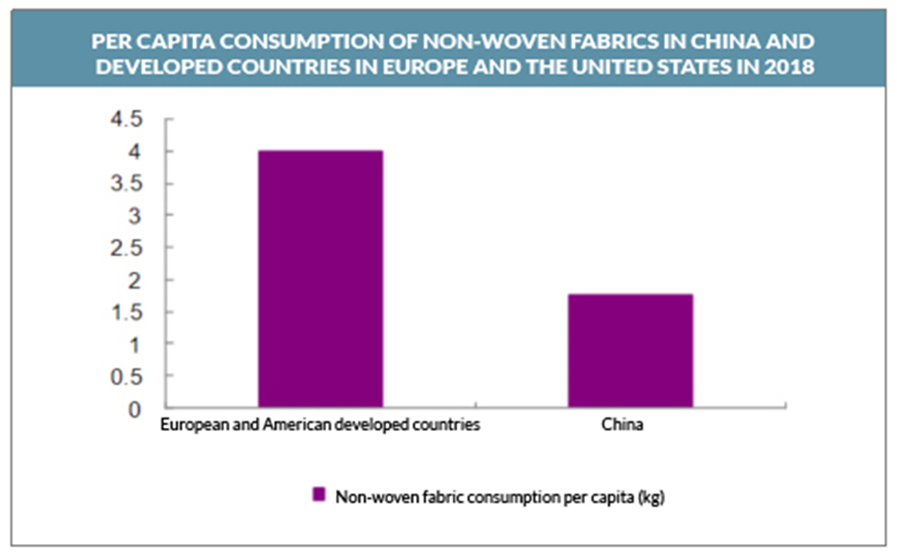

Due to gaps in income and consumption levels, China's per capita consumption of non-woven fabrics is at a relatively low level compared with developed countries. From the perspective of consumption structure, the largest application field of non-woven fabrics in China is medical care and health care, while 60%-70% of non-woven fabrics in the US market are used for medical, health and daily necessities, and in Japan, industrial, medical and sanitary products Non-woven fabrics consumed accounted for 57.4% of the demand. Due to the high cost of use, the proportion of non-woven fabric products used for disposable protection in China is far lower than that of developed countries, and there is still a lot of room for development in the consumption of medical non-woven fabrics.

European non-woven market situation

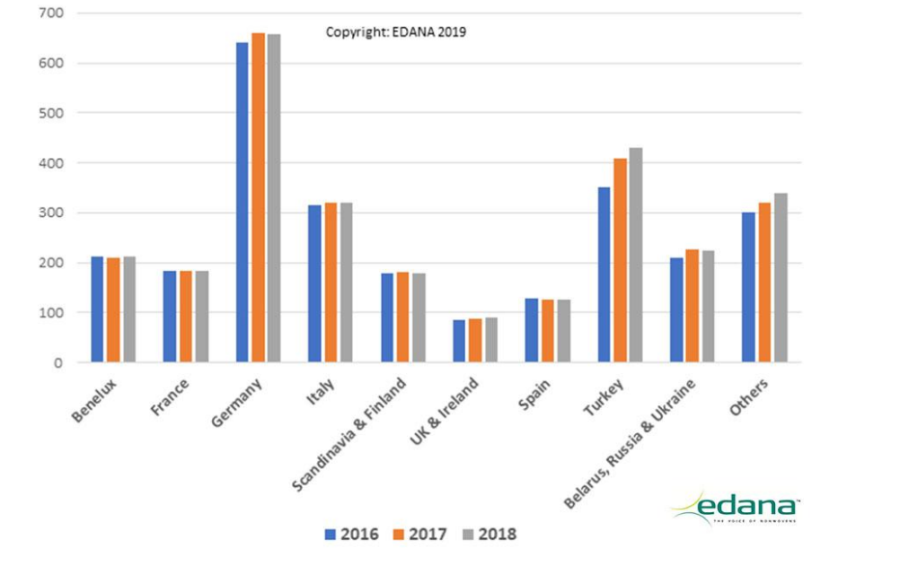

The world's leading European Nonwovens Association (EDANA) announced its annual survey report on the European nonwovens industry. The report provides a comprehensive overview of the European nonwovens industry, highlighting the driving force and sustainability of the industry during the period of dramatic changes in demand drivers and supply chains.

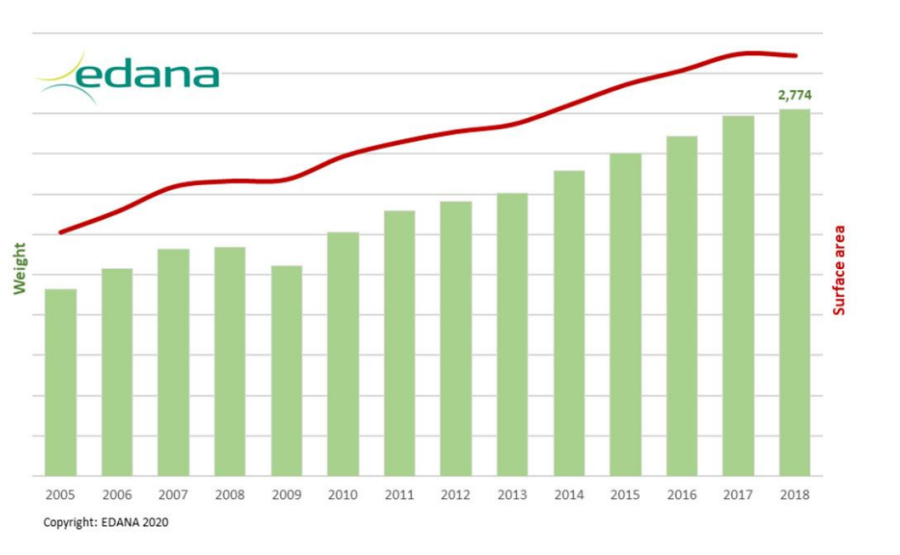

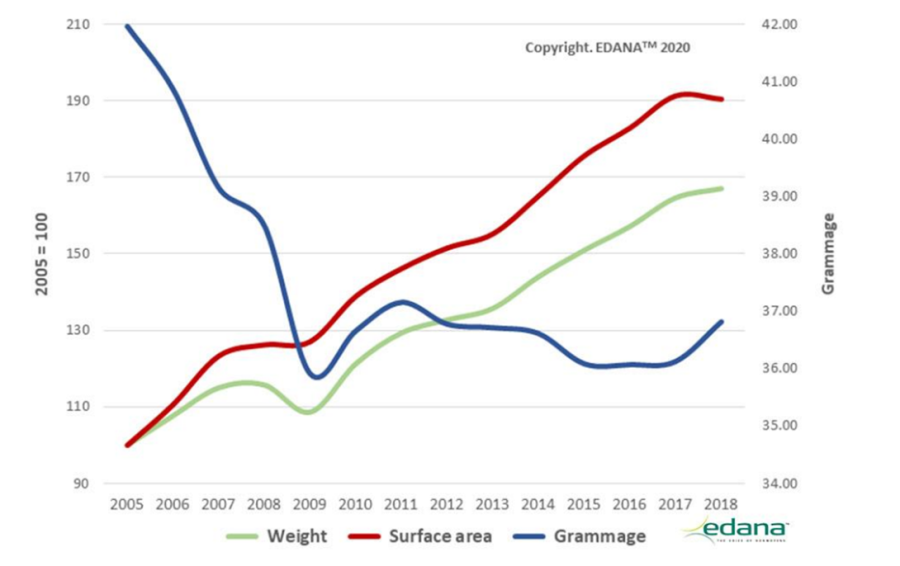

According to data from the EDANA report, in 2020, the output of nonwovens in Europe increased by 7.2% year-on-year, reaching 3.075615 million tons (approximately 85.9 billion square meters), and the market size reached 9.555 billion euros. The total output of the 27 EU member states has now exceeded 2.15 million tons.

In the past ten years, the average growth rate of nonwovens production in Europe was only 4.0%. Jacques Prigneaux, director of market analysis and economic affairs at EDANA, analyzed in detail the main driving factors behind the significant growth of nonwovens production in Europe in 2020: "High levels of anti-epidemic materials Demand has promoted the production growth of related industries. Spunbond and dry-spunlace nonwovens have achieved double-digit growth in production tonnage and area. Due to the development of similar applications, wet-laid nonwovens last year The growth of airlaid nonwovens is also considerable. The trend of airlaid nonwovens in different applications is the opposite, and the situation is the same as the previous year."

"The main end use of nonwovens is still the sanitary products market, accounting for 28% of the total delivery volume, reaching 857,940 tons, a year-on-year increase of 9.6%. Due to the new crown epidemic, the most significant terminal areas for nonwovens application growth in 2020 are Medical (+118.0%), wipes/personal wipes (+22.0%) and clothing (+32.6%)."

In contrast, automotive interiors (-23%), carpets, tablecloths and linings have experienced significant declines. In addition, several important durable goods industries, such as the construction market and the liquid filtration industry, have limited growth; while agricultural applications have experienced negative growth.

To ensure the stable development of the non-woven industry chain, it is necessary to ensure the production efficiency and production quality of non-woven fabrics. In order to stabilize the supply of non-woven fabrics during the epidemic,with 50 years of design experience and technology precipitation, China’s old-brand machinery manufacturing company suntech has developed and produced intelligent non-woven fabric machines based on the standards of "precision and intelligent manufacturing" including spunbonded non-woven fabric machines and spunmelt machines,Non-woven machine, melt blown machine, spunlace non-woven machine, etc.

(Suntech ST-SMS composite nonwoven production line)

The non-woven fabric produced can meet ISO and CEN standards to meet the production needs of downstream products such as diapers, wet wipes, protective clothing, masks, etc. At the same time, the production of non-woven fabrics requires a large amount of raw material including viscose fiber, polyester fiber, polypropylene fiber, etc. It also solves the problem of raw material sales for upstream non-woven raw material suppliers. suntech non-woven fabric machines focus on intelligent applications, help non-woven fabric production, create a one-stop non-woven fabric industry chain solution, and care for human health.

(Suntech ST-ASS spunbond nonwoven machine)