Search This Supplers Products:fabric inspection machinefabric rolling machinefabric folding machinefabric cutting machinewarp beam trolleybeam stacker

- Home

- About us

- Products

- Faqs

- Fabric Inspection Machine

- Fabric Folding Machine

- Fabric Cutting Machine

- Beam Stacker

- Digital Counter Meter

- Fabric Relaxing Machine

- Tubular Fabric Reversing Machine

- Tubular Fabric Slitting Machine

- Automatic Tube-Sewing Machine

- Hydraulic Warp Beam Trolley

- Motorized Warp Beam Trolley

- Cloth Roll Trolley

- Warp Beam

- SUNTECH Service

- Fabric Rolling Machine

- Fabric Roll Packing Machine

- Accessories

- Batcher Machine

- News

- Certificate

- Contact us

Why fabric roll fall out of the unwinding rollers?

There are two dancing rollers in the inspection machine:

the one near the inlet position is to synthesize the unwinding and inspection speed;

the one under the inspection table is to synthesize the inspection and rewinding speed.

The solution is:

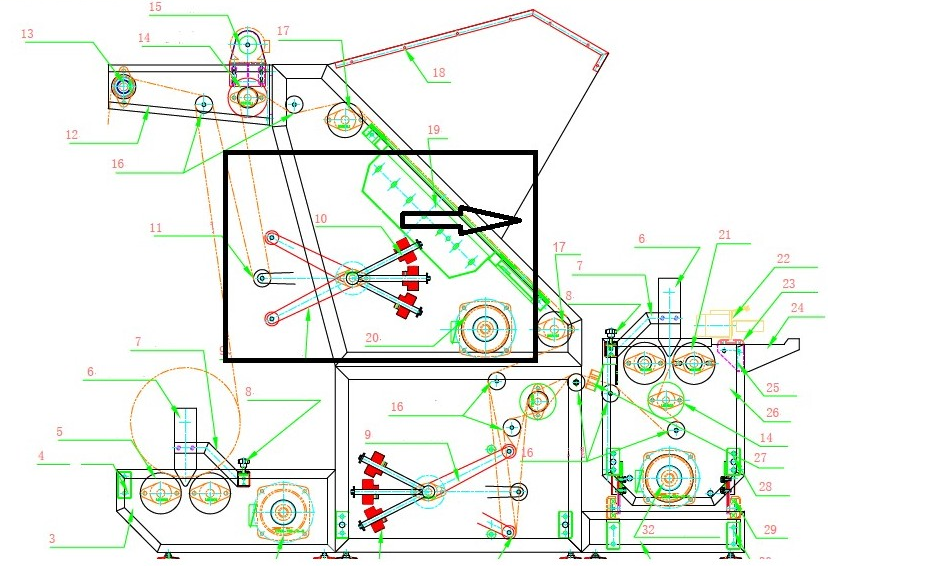

1. see below marked drawing, to adjust the counter weights to the right;

2. if the problem still there when the counter weights adjust to the right-most side, pls add extra counter weights.

Dancing Roller Working Principle:

When the speed is different, the potentionmeter in the dancing roller will send signal to the related inverter for the motor to adjust the speed to the same.

Now the fabric roll fall out of the unwinding roller when the dancing bar is in the up position, but it is fine when it is down.

This means in that moment(from down to up)there is no enough time for the potention meter to send signal to the inverter to adjust the speed into same level.

Our solution is to adjust counter weights to the right, or add more counter weights, so the dancing roller will rise to the top faster, which can send the signal faster.

Finally, the unwinding and inspection speed can be adjusted in the same level in time, so the fabric roll will notfall out.