Search This Supplers Products:fabric inspection machinefabric rolling machinefabric folding machinefabric cutting machinewarp beam trolleybeam stacker

- Home

- About us

- Products

- Faqs

- Fabric Inspection Machine

- Fabric Folding Machine

- Fabric Cutting Machine

- Beam Stacker

- Digital Counter Meter

- Fabric Relaxing Machine

- Tubular Fabric Reversing Machine

- Tubular Fabric Slitting Machine

- Automatic Tube-Sewing Machine

- Hydraulic Warp Beam Trolley

- Motorized Warp Beam Trolley

- Cloth Roll Trolley

- Warp Beam

- SUNTECH Service

- Fabric Rolling Machine

- Fabric Roll Packing Machine

- Accessories

- Batcher Machine

- News

- Certificate

- Contact us

ST-DFLM How to make sure fabric folded selvege to selvege

1. TAKE OFF ALL THE FABRIC FROM FOLDING MACHINE.

2. CHECK THE CLOTH GUIDERS, MAKE SURE THEY ARE SYMMETRICAL.

3. HOW TO SOLVE THE ‘’CREASE’’ ISSUE:

THE KEY FACTOR OF ‘’CREASE’’ ISSUE IS THE HEIGHT OF TRIANGLE FRAME.

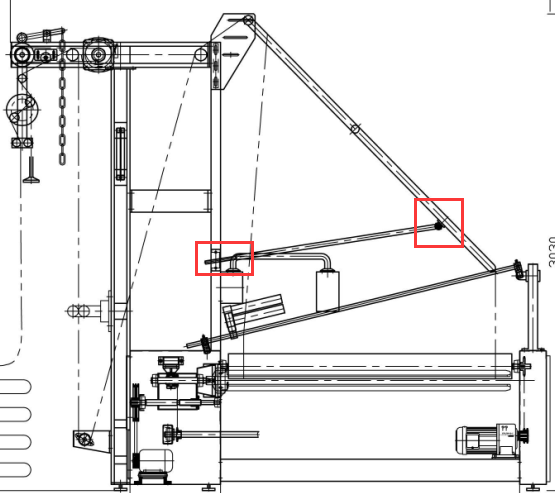

AND PLEASE ADJUST THE TRIANGLE FRAME TO A HIGHER POSITION BY BELOW TWO PARTS:

NOTE: PLEASE ADJUST THE TRIANGLE FRAME HEIGHT TO A HIGHER POSITION SIGHTLY, AND OPERATOR NEED TO ADJUST THE HEIGHT BASED ON DIFFERENT FABRIC TYPE.

4. HOW TO SOLVE THE ‘’EDGE-ALIGNMENT’’ ISSUE:

1) PLEASE SET THE BUTTON OF ‘’SENSITIVENESS ADJUSTING’’ BETWEEN 6 AND 7.

2) WHEN OPERATOR HAS FINISHED ALL ABOVE THREE STEPS, OPERATOR CAN LOAD THE FABRIC INTO THE MACHINE, SURELY OPERATOR NEED TO MAKE SURE THAT ALL THE FABRICS ARE IN WELL ALIGNED POSITION BY HAND BEFORE MACHINE STARTING.

3) THEN OPERATOR CAN START THE MACHINE SLOWLY, AND MAKE THE MACHINE RUN FOR A SHORT TIME, THEN STOP THE MACHINE.

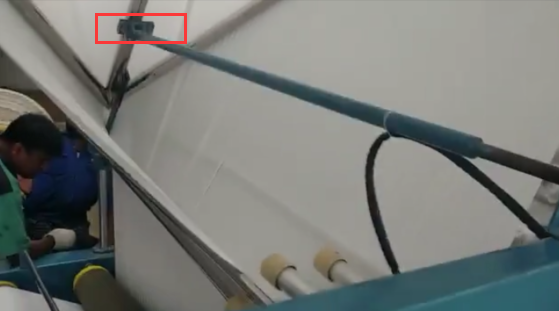

4) THEN AT THE POSITION OF EDGE-ALIGNMENT RASTER, OPERATOR NEED TO CHECK WHICH SIDE OF THE FABRIC EDGE IS DEVIATING, THEN OPERATOR NEED TO TURN THE ‘’BALANCE ADJUSTING’’ BUTTON TO MAKE THE RASTER MOVING TO THE CONTRARY SIDE, UNTIL THE DOUBLED EDGES ARE WELL ALIGNED. SO THE BALANCE ADJUSTING IS IN BEST PARAMETER.

AND THEN OPERATOR CAN RE-START THE MACHINE, WHICH WILL WORK PROPERLY.

FOR EXAMPLE, IN BELOW PHOTO, THE FABRIC EDGE IS DEVIATING TO OPERATOR’S RIGHT SIDE, THEN OPERATOR CAN GO TO THE CONTROLLER OF ‘’BALANCING ADJUSTING’’, AND TURN THE BUTTON TO MAKE THE EDGE-ALIGNMENT MOVE TO LEFT SIDE UNTIL THE FOLDED EDGES ARE IN WELL ALIGNED POSITION. THEN OPERATOR CAN RE-START THE MACHINE TO SEE PERFORMANCE.