Search This Supplers Products:fabric inspection machinefabric rolling machinefabric folding machinefabric cutting machinewarp beam trolleybeam stacker

- Home

- About us

- Products

- Faqs

- Fabric Inspection Machine

- Fabric Folding Machine

- Fabric Cutting Machine

- Beam Stacker

- Digital Counter Meter

- Fabric Relaxing Machine

- Tubular Fabric Reversing Machine

- Tubular Fabric Slitting Machine

- Automatic Tube-Sewing Machine

- Hydraulic Warp Beam Trolley

- Motorized Warp Beam Trolley

- Cloth Roll Trolley

- Warp Beam

- SUNTECH Service

- Fabric Rolling Machine

- Fabric Roll Packing Machine

- Accessories

- Batcher Machine

- News

- Certificate

- Contact us

What is 4 Point System on Fabric Inspection Machine

What is 4 Point System?

4 point system is a software for recording the fabric faults, which is installed on fabric inspection machine.

How to use the SUNTECH 4 Point System?

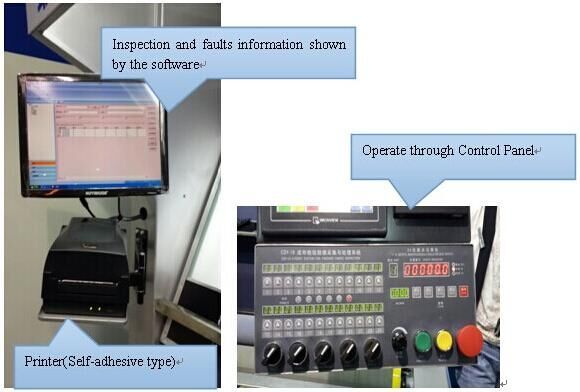

First Step: Install the software into the computer and connected the computer with the machine

(Usually if customer requires this system, we recommend them to buy the computer,software, printer together. We will install do the first step before exporting)

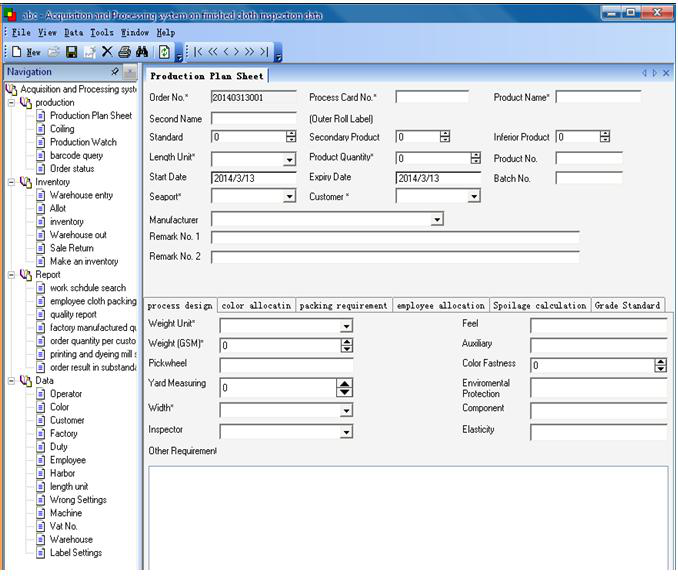

Second Step: Operator need identify 24 defects onto the software in the computer and the computer will record some general information you input like date, order, shift, operator's name, in the computer.

Third Step: When the operator found defects when inspecting, manually stop the machine, select defects and give penalty from 1-4 serious degree on operation panel.

Forth Step: The computer will record the type, the position and the serious degree of the detects as well as general information.The printer prints the results.

Why we do not recommend to install the 4 point system when there is on only one machine?

If you just have 2 sets of inspection machine, we don't recommend it, because the function just can used to record the general information and defect types, locations & serious degree. If you have 5 sets, 10 sets or more sets of inspection machine, this system also can connect together to be as a intranet, share all the information. The production manager could monitor every machine's processing on the head computer, manage production plan, control the inventory, analysis the statistics to improve the quality.

Since this system&software need to install into computer to use, we suggest you to buy it with computer, so that we can install the software into the computer along with machine, and you can use it directly when received the machine.

For this system, it work with printer to print out the Self-adhesive Paper. There has two tables you can print out, one is for general information like date, order No., batch no., operator's name, color etc.; another is defects information like defect type, location& serious degree.

About the marks you said, since this software just can record the defects location into computer and print out for you mark on roll; if you mean to mark each defect on fabrics, this need your operator do it by manual.